Get strong, durable anti-vibration parts.

We design parts with a geometry and rubber mix optimized to meet your requirements.

To achieve this, we carry out precise evaluations:

- Analysis of vibration modes and load axes.

- Addition of barriers or insulation to disrupt the path of noise and vibrations.

- Integration of noise absorbers or mass dampers specially designed to reduce the amount of vibration.

Trust Soucy Baron to absorb noise and vibrations.

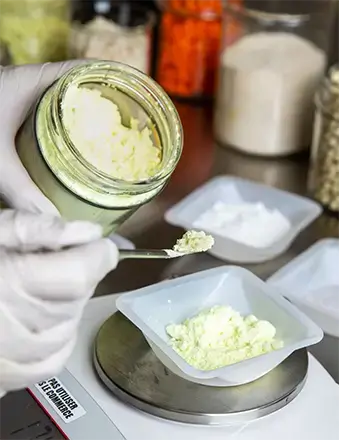

Our state-of-the-art expertise in polymer chemistry allows us to meet your technical requirements.

Each ingredient and additive is chosen to be in perfect balance with the type of elastomer, its composition, odorants, colour pigments and flame retardants.

Resistance to various fuels, oils, acids, alkalines, weathering, UV agents, ozone, heat, flame, abrasion, as well as low-temperature flexibility and gas impermeability are all chemical properties that will dictate the choice of materials.

These precise choices will come together to help us achieve the desired physical properties, in particular: static and dynamic rigidity, resistance to fatigue and tearing, and more.

Our savoir-faire allows us to combine the right ingredients to obtain the desired properties.

Create quality products with the help of our engineers.

The effectiveness of a rubber product depends on its mechanical properties and durability.

Extensive analyses and tests are carried out during the design of the parts:

- Characterization of elastomeric materials (non-linear behaviour)

- Finite Element Analysis (FEA)

- Product characterization to confirm modelled mechanical behaviour

- Evaluation of longevity

Soucy Baron is at your side to ensure the right static/dynamic stiffness, damping coefficient, transmissibility, or any other physical measure.

Modelling for Performance!

Improve the performance of your products by processing and bonding inserts with low-VOC adhesives.

Over the past 20 years, we have processed hundreds of millions of parts.

Rubber-to-metal bonding: thanks to our mastery of different adhesion techniques and our extensive knowledge of adhesive types, we create durable parts that combine the mechanical strength of a rigid structure (metal or plastic insert) with the flexibility of elastomers.

We respond to your adhesion challenges by using adhesives that will provide additional protection against corrosion, without adding a step in the treatment of the part.

Combine strength and flexibility in all your projects!

Rubber and silicone overmolding involves coating a metal component to improve its structural properties.

This method ensures that the desired physical and mechanical properties for the application of the part are achieved.

Done by compression, injection, or transfer, overmolding reduces production time, manufacturing costs, and additional assembly and finishing steps.

For maximum quality, we work with:

- Steel, for its cost

- Stainless steel, for its resistance to corrosion

- Aluminum, for its lightness

Optimize the performance and properties of your rubber parts!

Soucy Baron has put in place a quality assurance program to support compliance and consistency in its key industrial and manufacturing processes.

We are ISO 9001:2015 certified and our quality control system ensures:

- Rigorous methods and processes

- Traceability of manufactured products

- Increased customer satisfaction

- Continuous improvement across the board

All of our products comply with relevant industrial requirements, such as REACH and ASTM depending on the application.

Constant quality control is guaranteed!

To meet your highest needs and requirements, we conduct continuous quality inspections that include

- compounds and raw materials

- mixtures of each batch

- compliance and dimensional verification of finished products

Our metrology laboratory allows us to perform physical performance tests:

density, hardness, rebound, tensile strength, compression, tensile and heat resistance and much more.

Once these tests have been carried out, we analyze the results to design any necessary improvements to optimize the behaviour of the part.

Rely on Soucy Baron for worry-free projects!

We are part of a small circle of : Controlled Goods Program (CGP)-certified companies., Established by the Government of Canada, this program includes all the provisions of the International Traffic in Arms Regulations (ITAR).

Whether you work in aerospace, defence or other industries that require a high degree of security, ensure that your parts and records are protected by strict security measures.

We guarantee the confidentiality of the intellectual property of your components.

Rigorous confidentiality and security for your projects!

.jpg)